eCutout™ Radiation Shields

Utilising advanced design and CNC capabilities , 3D One has developed streamlined processes that create a precise, customised shield that allows Healthcare Professionals to deliver accurately contoured electron radiation therapy whilst minimising exposure to healthy tissue.

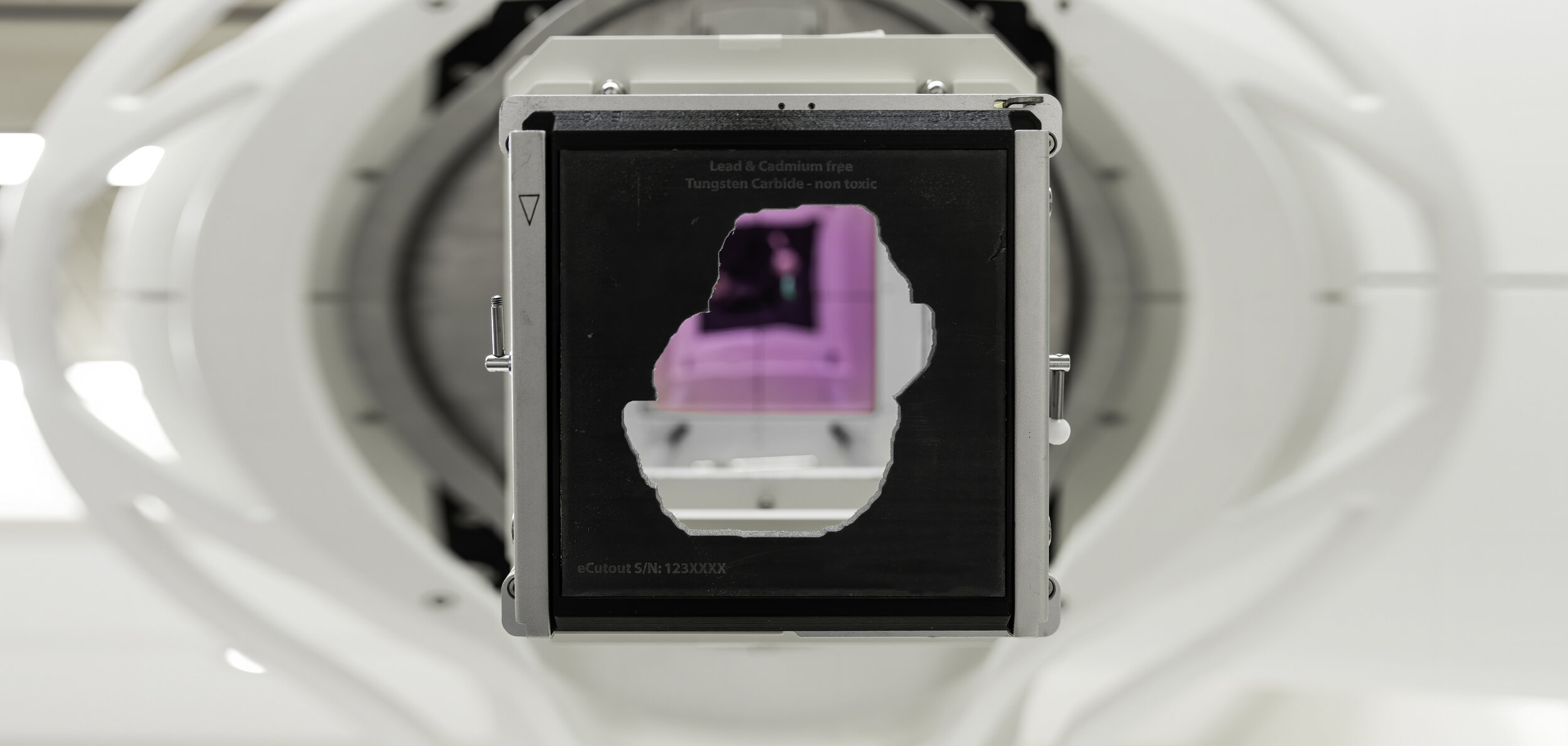

Tungsten Carbide has equivalent electron shielding performance to lead, but is non-toxic and able to be physically handled, as well as being reclaimable. The 3D One eCutout™ is a vendor-specific (Elekta or Varian) electron therapy shield , consisting of a 3D printed plastic frame filled with a proprietary Tungsten Carbide composite, incorporating a high precision water-jet cut aperture .

3D One provides on-demand custom-designed eCutouts™, efficiently and rapidly via its online orders portal, where clinical centres can upload patient-specific treatment aperture profiles, as well as optionally use of the purposely designed GUI for offset, labelling and orientating purposes.

What makes the 3D One eCutout™ better?

Customised and patient specific:

eCutout™ are produced on-demand to specifically match unique patient needs.

Highly focused therapy that protects healthy tissue:

Advanced design and manufacturing technologies facilitate highly contoured apertures that precisely match the patient’s electron radiation therapy prescription.

Automated process for fast turnaround:

Design and manufacture is streamlined for fast, highly accurate production and delivery to your clinical centre.

Non-toxic attenuating material:

eCutout™ are safe-to-handle radiation shields that reduce the risk to clinical team members.

Reclaimable, recyclable and reusable products:

eCutout™ are non-toxic and safe, eliminating the need for resources and infrastructure to deal with hazardous material.

A safer solution for patients and hospital staff

Traditional radiation shields commonly use LMPA (low melting point alloy), which is toxic and hazardous. It creates a serious health concern for hospitals and requires expensive infrastructure to mitigate. Even then, the Lead and Cadmium in the LMPA remains a risk to clinical team members. The eCutout™ uses an attenuating lead-equivalent Tungsten Carbide composite.

The vendor-specific frame is 3D-printed using PLA (poly-lactic acid), creating an electron shield that is safe and non-toxic. It is a safer, more effective option for radiation therapists, physicists, oncologists and other hospital staff.

Created to exact specifications

The eCutout™ is produced using advanced design and manufacturing techniques. It combines a frame of biodegradable poly-lactic acid, filled with an attenuating tungsten carbide composite material. The precise, custom aperture within the shield is water-jet cut.

The Result Of Rigorous Real-World Testing

3D One’s eCutout™ is the result of extensive pre-clinical testing and trials in a collaboration between our R&D Team and Brisbane’s Radiation Oncology Mater Centre.

During testing, we examined the dosimetry of the eCutout™ by measuring: Transmission Relative dosimetry (percentage depth and penumbra), and Insert factors For all electron energies (6, 9, 12, 15 and 18 MeV) at both 100cm and 110cm on a Varian Clinac IX, for a range of square applicator dimensions (6 cm to 15 cm), with aperture dimensions ranging from 1.9 cm to 14.25 cm.

The transmission tests demonstrated that the eCutout™ attenuating material is equivalent to the traditional LMPA for 6-18 MeV to within ∓ 0.5%. Our test results proved that, dosimetrically, the eCutout™ can be used as an alternative to Low Melting Point Alloy (LMPA) .